A sustainable approach to beverage packaging

Improving your beer and wine packaging can not only help optimise your supply chains, but also reduce your overall impact on the environment.

Fermentation is one of the oldest methods of producing drink that is both safe and delicious. Going back to medieval times, fermented ‘small beer’, would have been produced and drunk locally by all ages and at all times as a safer alternative to water, which was often contaminated.

One major difference today is that the production of beer and cider are not always close to consumption. Instead, brewing is a key process at the intersection of international supply chains, and these supply chains are under extreme pressure.

A second key difference is the need for this industry to lower the carbon footprint of processes, logistics and products, reducing packaging that cannot be reused or recycled and adopting sustainable alternatives.

Enabling efficiency

It is more than possible to achieve these demands in tandem.

Optimised packaging can have a cascade effect on supply chains, adding efficiencies at every stage and at scale.

For example, lighter packaging through the use of corrugated board means reduced inbound and outbound transportation costs day in, day out.

In the same way, tailoring the size and shape of packaging will lower the number of pallets used and increase the total number of units it’s possible to fit in a warehouse or container.

If the packaging is designed for reuse and recycling, the circular economy is a logical next step and something more than simply an ambition – it becomes an achievable goal.

Circular design in action

Decreasing environmental impact is a key ambition for all businesses and packaging plays a key role. It makes supply chains both more efficient and more sustainable by acting as an enabler of the circular economy rather than being simply a waste product.

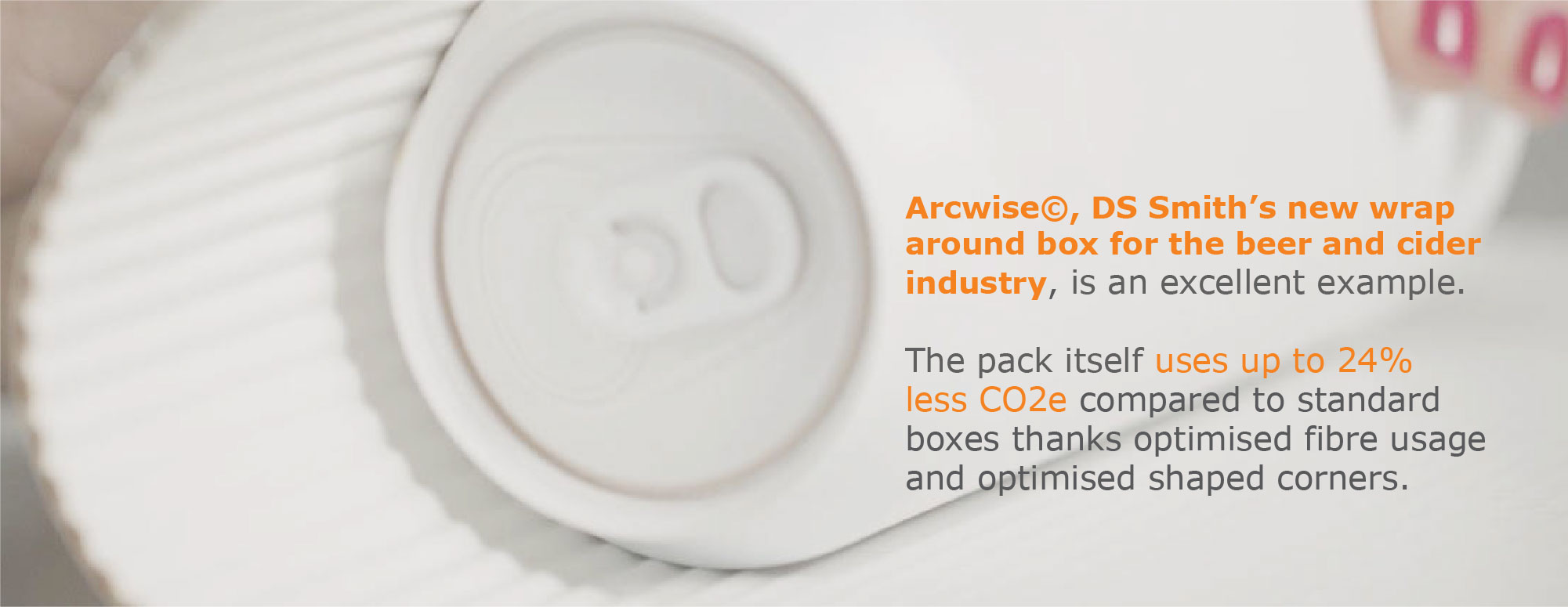

In addition, Arcwise® is twice as stable when stacked compared to 0201/RSC boxes and will not be crushed in the corners by stretch-film as square boxes can be. You can also use less plastic by reducing the thickness of shrink film by up to 20% while maintaining a stable pallet.

Finally, these Arcwise® packs have a premium feel that differentiates them more clearly from competing brands and ‘pops’ on the shelf. Packs are also more practical for consumers because they can be carried easily.

For brewers, this is a key benefit – to achieve ambitious CO2 reduction targets through innovation.

And that’s no small beer.