Fulfilling the potential of packaging

Taking a closer look at the impact of packaging on the Automotive Industry

Fewer than one in five automotive firms would consider investing in packaging to improve efficiency and sustainability across their supply chain. Why is this number so low? Efficiency is not a new concern. More efficient production means better margins. With energy costs and supply chains now at breaking point, challenging existing relationships and refocusing on efficiency is prudent business.

Like falling dominos, improvements to packaging have knock-on enhancements. For example, tweaks of millimetres to packaging can mean many more individual packages loaded into a single container, and more efficient shipping and haulage. At scale this represents significant savings to logistics and reductions to carbon footprint, but does not necessarily mean everything is recyclable – sometimes dedicated reuse trumps recyclability.

New global research from DS Smith explores the attitudes of supply chain and sustainability managers in four major sectors.

Decarbonising transport

On the supply side, automotive manufacturers understand the need to drive down emissions, with hybrid and electric vehicle sales more than doubling to almost 7m in 2021- a trend set to continue in 2023. Behind the scenes, greater opportunities to lower carbon footprints in manufacturing and logistics are left on the table as complex supply chains rumble on.

Circular economy principles combined with innovative packaging mean it’s possible to make drastic improvements to overall efficiency and sustainability through recycling and reuse. Using circular-ready packaging is one of the levers automotive companies can use in order to reduce their CO² footprint.

Bumper to bumper

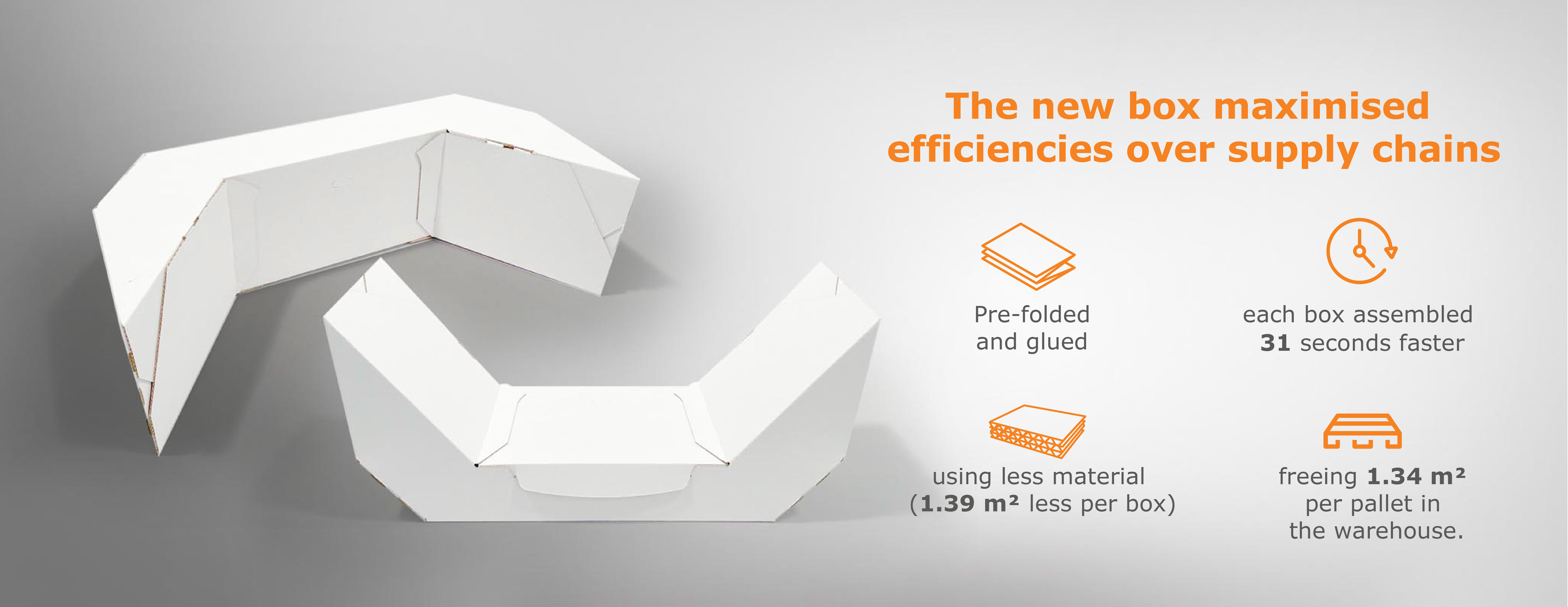

One solution we developed for automotive customers concerns the transportation of bumpers, which are difficult to ship because of their relative fragility and inconvenient shape.

The original box could be stacked perfectly for stable transit but were bulky and slow to assemble. Boxes could be improved based on our Circular Design Principles. These measure sustainability of packaging in eight different ways to make it ready for the circular economy and collaboration with PackRight centres.

More importantly, the new box improves protection and reduces transportation costs because it is stronger, lighter, and designed to maximise the number of units that can be loaded into a single container. The box itself is one way to streamline the supply chain. For the 80% of automotive manufacturers who want to improve logistics and reduce carbon footprint, innovating packaging can produce a cascade of positive effects, and now is the time to see what you can save.